When selecting gas detectors for enclosed parking garages, boiler rooms, or other enclosed spaces, where carbon monoxide (CO) and nitrogen dioxide (NO₂) can accumulate, the stakes are high. A detector that fails or underperforms could mean unsafe conditions for building occupants, unnecessary ventilation cycles that waste energy, or even fines for noncompliance.

Choosing the right detector isn’t about picking the cheapest model off a spec sheet; it’s about balancing safety, reliability, and efficiency with code compliance.

In this article we’ll discuss five questions that you should consider when selecting a gas detector.

While commercial garages and mechanical rooms may offer some protection for the elements, it’s still important that a gas detector has been designed to withstand some abuse.

Even in an enclosed parking garage, gas detectors may encounter temperature fluctuations, humidity, dust, and corrosive vehicle exhaust (all of which can shorten the life of sensitive electronics if the detector isn’t designed properly). That’s why choosing a detector built for the real world, not just the lab, is essential.

Look for sealed enclosures that prevent moisture and dust from compromising sensor performance. Industrial-grade components rated for temperature extremes provide assurance that the detector won’t fail on a hot summer afternoon or during a winter cold snap. A proven track record in similar facilities is also invaluable; choosing a device that has been deployed successfully in parking garages and boiler rooms ensures you’re not testing unproven technology at your expense.

A gas detector that drifts out of calibration poses two risks: false alarms that unnecessarily activate ventilation systems and, even more concerning, missed detection of dangerous gas levels. Both outcomes are costly—one wastes energy, the other compromises safety. That’s why long-term accuracy is a key selection factor.

High-quality detectors typically use electrochemical sensors for gases like CO and NO₂, which offer excellent stability over time. Look for devices with extended calibration intervals (six to twelve months is typical) and built-in diagnostics that continuously monitor sensor health. These features reduce maintenance costs while ensuring you can trust the readings on the display. Some advanced systems can even alert you proactively when a sensor begins to drift, so you can address the issue before it affects safety.

Gas detection is rarely a standalone system. In garages and mechanical rooms, detectors must communicate with ventilation fans, BMS platforms, and sometimes fire alarm panels. Poorly designed detectors can add complexity to this integration, requiring extra interface modules or custom wiring.

The best detectors are designed for flexible integration out of the box. Multiple output options (4–20 mA, relay contacts for fan activation, and digital protocols like Modbus or BACnet) give you options whether you’re tying into a brand-new controller or retrofitting an existing system. This flexibility can significantly reduce installation time and avoid headaches for contractors. In larger projects, some vendors also provide wiring diagrams and sequence-of-operation documents, which streamline commissioning and ensure the system is installed correctly.

Even the best detectors are only as valuable as the support behind them. If a supplier can’t deliver within your project timeline or isn’t available to answer installation questions, the risks are passed to you. This makes supplier support and product availability critical factors.

Look for manufacturers or distributors with US-based support teams that can provide rapid shipping and same-day technical assistance. Equally important is the ability to source replacement sensors or calibration equipment without long delays. Some suppliers also offer commissioning services or remote support to help with troubleshooting in the field, which can save hours during a tight project schedule.

Finally, no gas detection system is complete without compliance. Codes and standards don’t just exist to satisfy inspectors; they ensure occupant safety and energy efficiency. In enclosed garages and mechanical rooms, compliance typically means meeting requirements from building codes, occupational safety organizations, and product certification bodies.

The right detector should carry certifications such as UL 2075, which validates its suitability for use in life safety systems. It should also be designed to comply with ventilation requirements in the International Mechanical Code (IMC), which allows demand-controlled ventilation based on CO levels. Beyond that, exposure limits set by OSHA, NIOSH, and ACGIH provide clear guidance on safe operating thresholds, and detectors should be capable of monitoring within those ranges. Choosing compliant equipment ensures smoother inspections, reduces liability, and provides peace of mind that your system is protecting both people and property.

Choosing the right gas detector isn’t just about hardware specs; it’s about protecting people, meeting code, and ensuring smooth operation of your facility. A well-chosen detector will be rugged enough to survive the environment, accurate enough to be trusted, flexible enough to integrate seamlessly, supported well enough to keep projects on schedule, and certified to meet the latest safety codes.

By investing in the right solution, facility managers, engineers, and contractors can strike the right balance between safety, efficiency, and peace of mind.∎

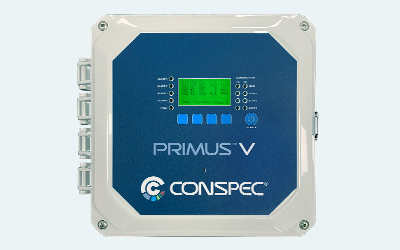

At Conspec Controls, we design and build gas detection systems that check every box: rugged enough for harsh environments, accurate over the long term, simple to integrate, industry-leading availability, and fully compliant with all relevant codes and standards.

Whether you’re managing an enclosed parking garage, a boiler room, or another commercial space where gas detection is required, our experts can help you specify the right solution with confidence.